The long-range radar sensor is intended for the real-time positioning of objects on distances up to 1,000 m with an accuracy of 1.5 mm.

The radar operates in 76-77 GHz license-free band and is a robust millimeter wave distance measurement sensor for industrial applications in any harsh environment.

TPS-76A radar long-range position detection and tracking system is intended for precise and reliable position detection, even in harsh environments. It operates both indoors and outdoors on distances up to 1000 m and uses millimeter wave 76 GHz radar sensor with an active responder unit for ultra-precise positioning of the target.

TPS-76A positioning radar sensor is used for places where high measurement accuracy is required, but parasitic reflections from other objects are present. For example, when positioning rail cranes in the workshops of factories, cranes in ports and in the industrial sites of large enterprises that send products by rail.

Why is it important to use an active radar transponder instead of a passive corner reflector? When there is a piece of hardware near the object being tracked, it interferes with the measurement. For example, when positioning cranes, some close structures such as a fence or motor casing can reflect stronger than a corner reflector and measurement errors are possible. On the contrary, when using an active responder, we measure the true distance to the target.

Besides, with using the active responder, the radar response is “clean”, and not smeared because of nearby structures. This allows you to apply mathematical signal processing for a single-point target and thus achieve precise measurement accuracy.

TPS-76A Real-time Position Tracking Radar Applications

ELVA-1 76 GHz Real-time position tracking radar sensor can be used in various industrial applications and construction projects to improve safety, efficiency, and productivity. Here are some examples:

- Industrial plants: Real-time position tracking radar can provide accurate positioning data for heavy equipment, including cranes and coal loading machines, even in harsh weather conditions or low visibility. This data can help operators ensure that the equipment is positioned correctly and accurately loaded or unloaded.

- Mining: Real-time position tracking radar is used in the mining industry to monitor mines for rock movements and heavy equipment to ensure they are operating efficiently and safely.

- Oil & Gas: Real-time position tracking radar can be used in oil and gas exploration to track the inclination and shifting of drilling equipment and accident prevention.

- Construction: Real-time positioning radar can be used in construction to track the movement and tilt of buildings and heavy structures such as cranes.

![]()

- The top graph is RAW data.

- The middle graph is FFT (Fourier Transform. Reflected signal spectrum) and target mark.

The X-axis position is the distance. - The lower graph is the distance between the radar Unit#1 and Unit#2, shown on Y-axis. On the X-axis is time.

The lower graph shows the processing speed when micro-moving of Unit#2 from the fixed Unit#1. For testing, we put two radar units at a distance of 354 meters and moved Unit#2 back and forth in microsteps.

TPS-76A Real-time Position Tracking Radar Specifications

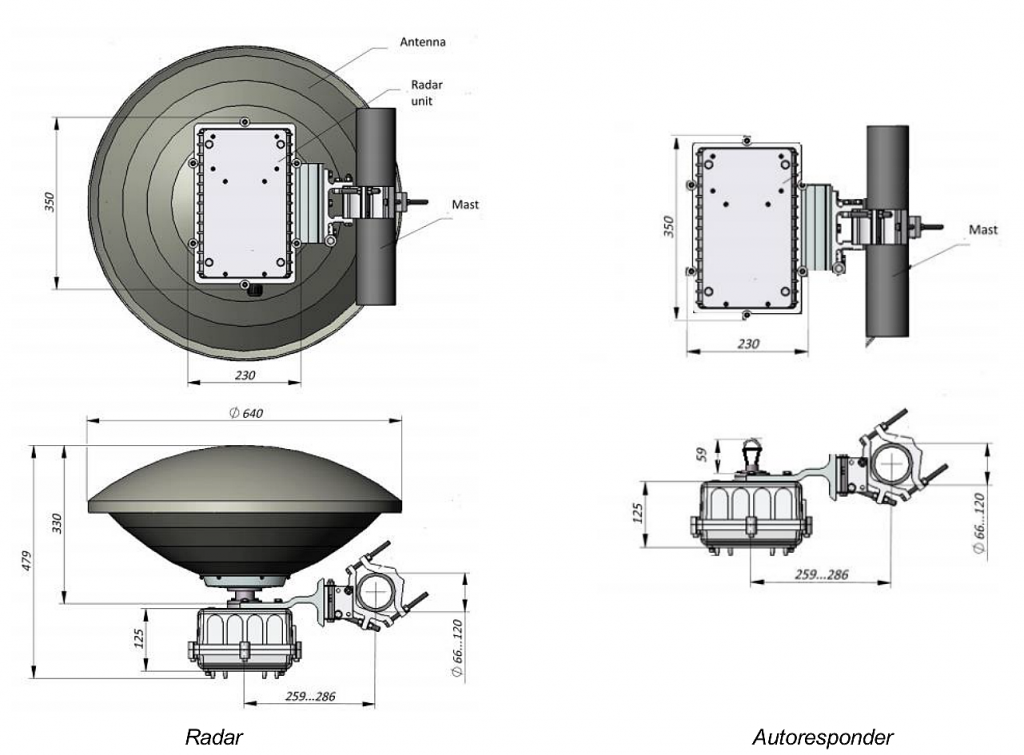

The radar sensor can be equipped with different antennas from 10 cm to 60 cm in diameter for Unit#1.

The basic Unit#1 is equipped with a 30 cm antenna, which allows the monitoring of targets at a distance of up to 500 m.

- Center frequency: 76.5 GHz

- Frequency sweep: 1.0 GHz

- Tx power: 7 dBm

- Active response IF

- Max measured distance: 500 m (for 30 cm antenna)

- Max measured distance: 1000 m (for 60 cm antenna)

- Accuracy: ±0.0015 m

- Digital output: Ethernet, UDP

- Power supply both for radar and responder: 24 VDC 20W for each unit

Additional software for radar output data conversion can be developed by the ELVA-1 team according to customer’s requirements.

TPS-76A Real-time Position Tracking Radar Drawings