MRTR-76 Millimeter-Wave Radiometer

The MRTR-76 is an advanced radiometric system for measuring the molten metal temperature in various types of furnaces used in metallurgical production. Using millimeter-wave technology to penetrate smoke and dust, the MRTR-76 ensures accurate temperature readings in even the most extreme furnace conditions, allowing for better control, reduced energy consumption and other operational costs, and improved metallurgical process efficiency.

- Most common techniques of measuring metal temperatures, such as using thermocouples, have several disadvantages. Thermocouples are typically utilised for single-use applications and each new measurement requires the consumption of a new thermocouple. In addition, thermocouples do not allow for continuous real-time monitoring of molten metal temperature.

- Other measurement methods, such as infrared thermal imaging cameras, could be effective at the metal pouring stage but are unable to reliably determine the temperature inside the furnace itself due to the dense smoke and dust cloud saturated with metal particles.

With millimeter-wave radiometry in the 75–110 GHz range, the MRTR-76 penetrates thick smoke and dust inside the furnace, delivering accurate temperature measurements where optical and infrared sensors fail. The system is ideal for environments with intense smoke and harsh furnace conditions, ensuring reliable operation over long periods.

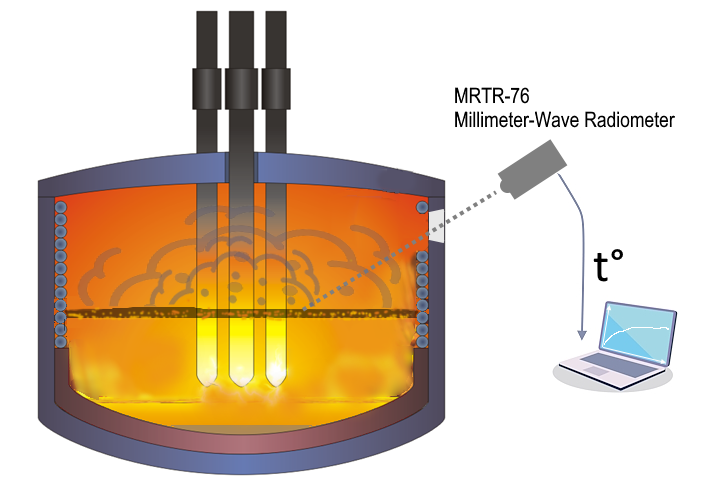

How radiometric measurement of molten metal temperature works

The environment inside the furnace is extremely aggressive: in the space above the metal mirror there is an intense movement of smoke and dust, but it is the millimetre radio waves that are able to penetrate these obstacles.

For the radiometer to be used successfully, the antenna’s field of view must be allowed to reach the observation area. In electric arc furnaces, this can be realised through special viewing windows that allow the instrument to record temperature readings in real-time. Radiometric temperature measurement thus provides metallurgists with an effective tool for optimising smelting processes. Continuous monitoring of the metal temperature is achieved through radiometer calibration, ensuring optimal melting conditions, efficient heat transfer, and improved metal quality.

Why Choose MRTR-76?

- Accurate Molten Metal Temperature Measurement: The MRTR-76 measures the temperature of molten metal by analyzing the thermal radiation emitted from the molten metal, ensuring reliable results.

- Penetrates Smoke and Dust: Unlike infrared pyrometers, which are obstructed by furnace gases and particles, the MRTR-76 effectively captures temperature data in the most challenging conditions.

- Continuous, Non-Contact Monitoring: Provides real-time data without the need for consumable thermocouples, reducing maintenance and operational costs.

- Modular and Adaptable Design: The system can be customized for different furnace types and measurement locations, ensuring optimal integration with your process.

- Seamless Industrial Integration: Compatible with both digital and analogue industrial networks, allowing real-time data transfer and automation system integration.

| Method | Smoke & Dust Resistance | Continuous Measurement | Contactless | Requires Maintenance |

|---|---|---|---|---|

| Thermocouples | Yes (must be inserted into metal) | No (single-use, periodic) | No | Yes (wears out) |

| Infrared Pyrometers | No (blocked by smoke/dust) | Yes | Yes | Moderate (lens cleaning required) |

| ELVA-1 Radiometer | Yes (penetrates smoke/dust) | Yes (continuous real-time data) | Yes | Minimal (no direct exposure to extreme heat) |

Use MRTR-76 for a variety of high-temperature metallurgical applications

The MRTR-76 Millimeter-Wave Radiometer is designed for a wide range of high-temperature metallurgical processes, ensuring precise temperature measurement in environments where traditional methods fail. This advanced system is suitable for:

- Electric Arc Furnace (EAF) Tapping Temperature Measurements: Accurately monitor tapping temperatures to improve energy efficiency, optimize melting cycles, and enhance overall process control.

- Basic Oxygen Furnace (BOF) Process Monitoring: Maintain optimal steelmaking conditions by continuously tracking temperature changes during oxygen blowing and decarburization.

- Induction Furnace Control: Ensure precise heating and alloying by monitoring temperature variations in induction melting applications.

- Cupola Furnace Temperature Optimization: Improve cast iron production by achieving stable thermal conditions and reducing energy waste.

- Blast Furnace Operations: Monitor and optimize molten iron temperature to enhance efficiency and prolong refractory lifespan.

- Reverberatory Furnace Melting Processes: Maintain stable temperature profiles for efficient aluminium and copper alloy production.

- Rotary Kiln Furnace Process Control: Ensure consistent heating for material processing in cement, lime, and metallurgical applications.

- Vacuum Induction Melting (VIM) Furnace Monitoring: Achieve high-purity metal production through precise, non-contact temperature measurement in vacuum environments.

- Vacuum Arc Remelting (VAR) Furnace Temperature Stability: Control remelting conditions for superior ingot quality in high-performance alloys.

- Ladle Furnace (LF) Continuous Temperature Tracking: Monitor ladle refining processes to optimize alloying and improve steel homogeneity.

With its ability to penetrate smoke and dust in the furnace, the MRTR-76 ensures accurate temperature readings in even the most extreme furnace conditions, allowing for better control, reduced operational costs, and improved metallurgical process efficiency.

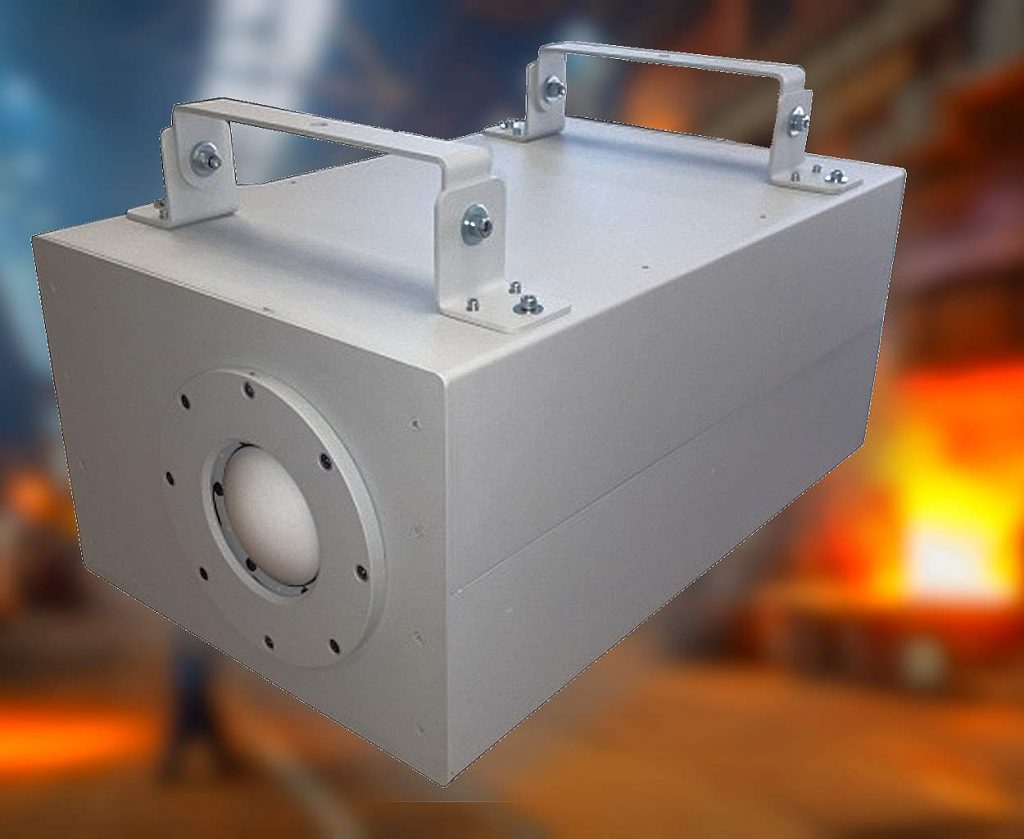

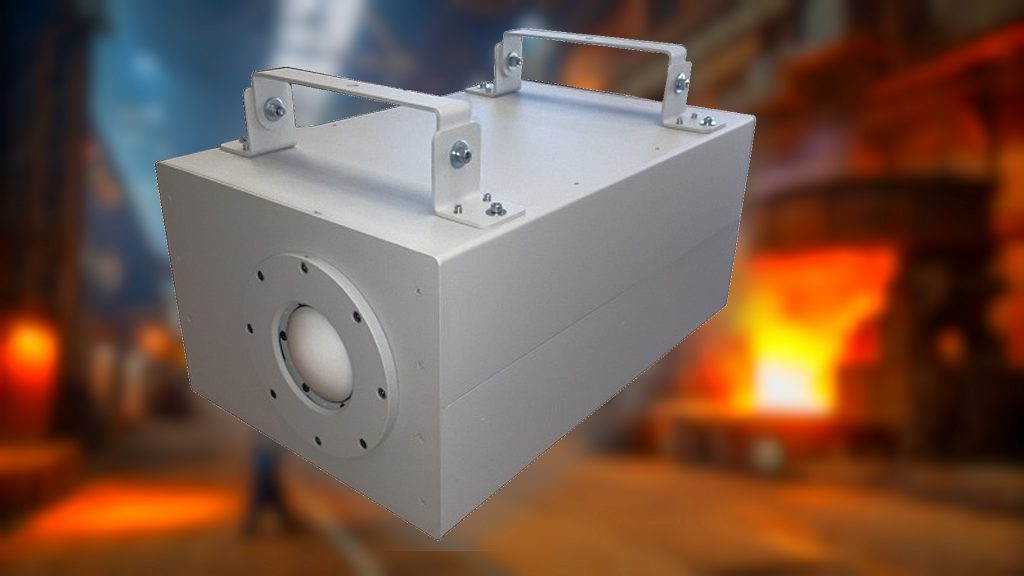

Robust Design, Optimized for Harsh Environments

The MRTR-76 is housed in a rugged, double-walled, air-cooled enclosure, protecting the sensitive electronics from extreme furnace temperatures and dust accumulation. A dedicated air-purge system ensures the antenna remains clean for uninterrupted measurements.

The MRTR-76 millimeter-wave radiometer features a compact lens antenna designed for precise temperature measurement in high-temperature metallurgical environments. Since the antenna is not built to withstand extreme heat exposure, the device has to be installed several meters away from the furnace inspection window and aimed at the target measurement area inside the furnace. The radiometer’s housing can be customized to meet specific operational conditions near different furnace types.

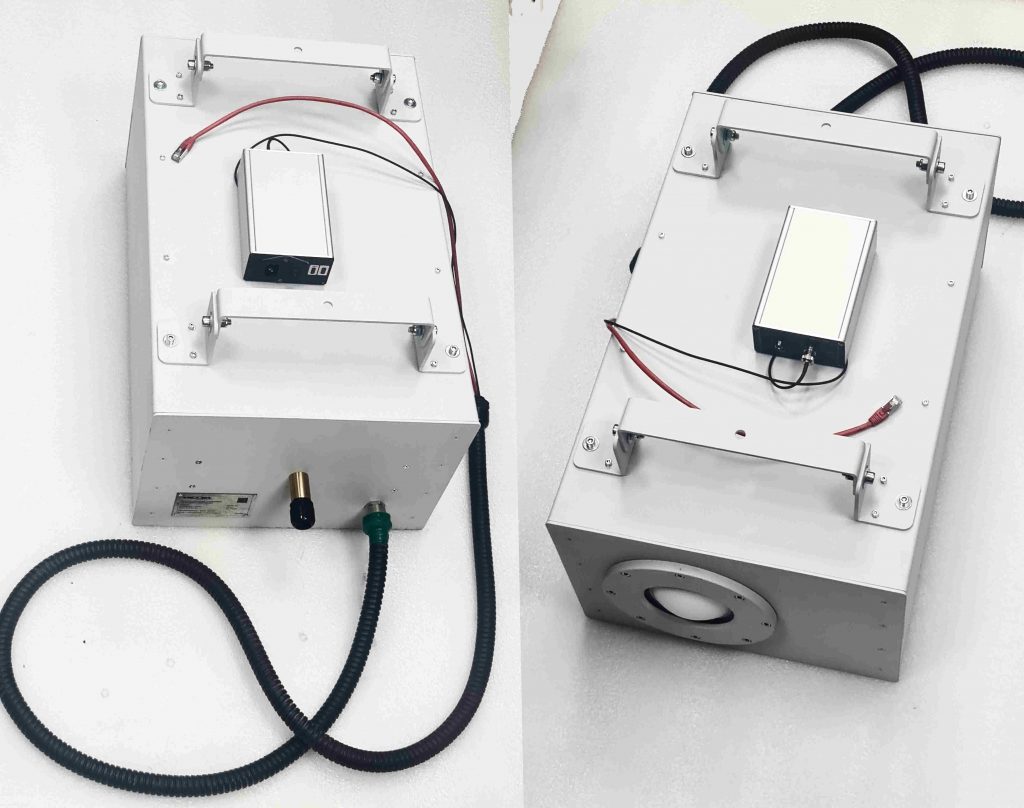

The rear panel of the MRTR-76 radiometer includes:

- Power connector

- Computer interface port for data transmission

- Air fitting for connection to the air supply system to maintain a clear antenna view

The MRTR-76 radiometer software provides a range of powerful features for real-time temperature monitoring and analysis:

- Ethernet connectivity for seamless integration with a laptop or remote server

- Live temperature display and historical data tracking with customizable time scales and data averaging

- Automatic or manual temperature scale adjustment for precise readings

- Temperature change history logging in CSV format with timestamped records

- Monitoring and logging of internal radiometer component temperatures to ensure stable operation

- Real-time emissivity adjustment, allowing users to compensate for variations in material emissivity for more accurate readings

With its built-in calibration features, the MRTR-76 ensures an accurate correlation between measured radiation and the actual temperature of molten metal. To achieve precise temperature readings, the instrument is calibrated by comparing its measurements with thermocouple readings during setup. This allows metallurgists to monitor and control furnace conditions with exceptional accuracy.

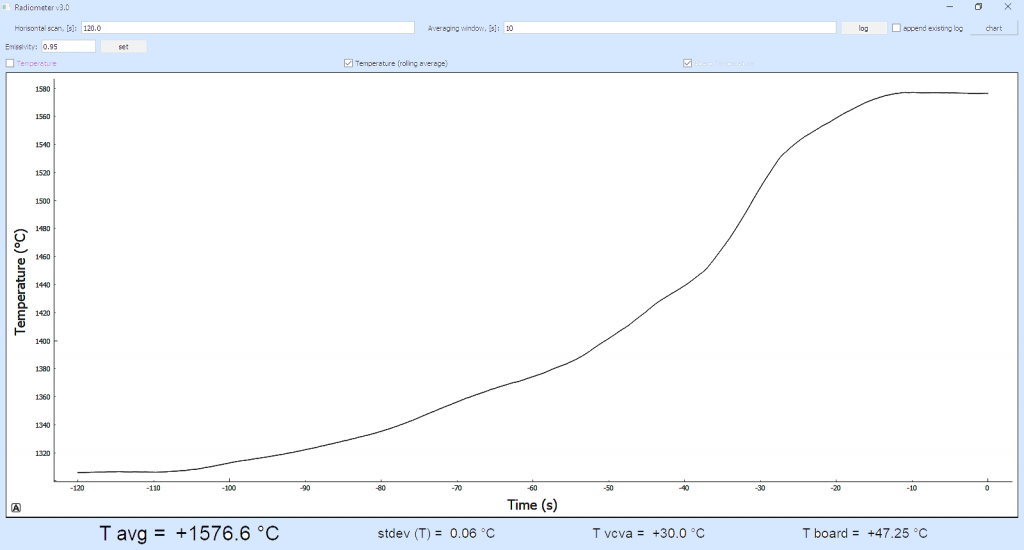

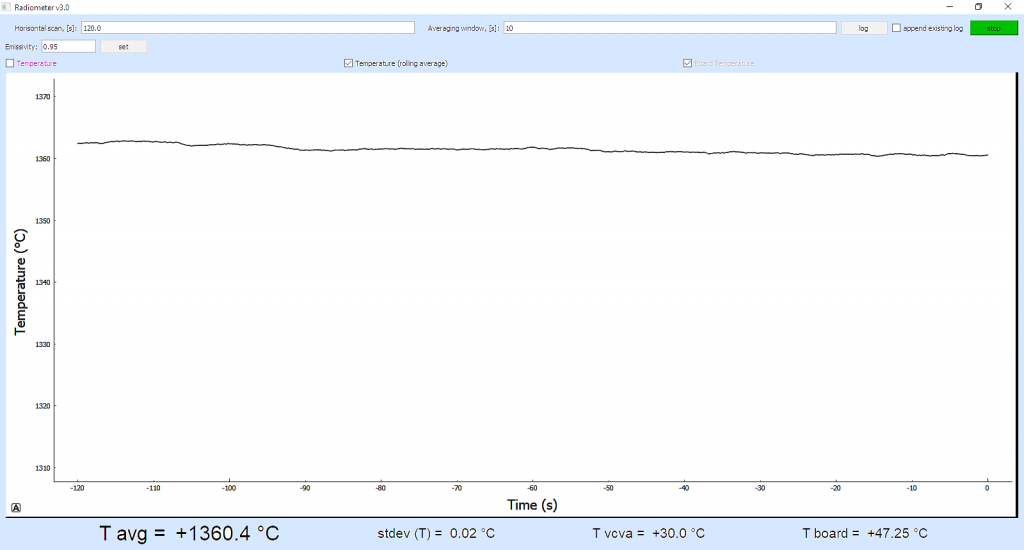

Examples of temperature measurements using a radiometer:

| Microwave frequency range | 75-110 GHz |

| Temperature measurement range | 75÷2500 K (-200÷2200° C, -320÷4050 F ) |

| Sensitivity (resolution) | No worse than 0.1 °С |

| Communication interfaces | Ethernet, Wi-Fi |

| Frequency of temperature information updates | 0.1 s on the chart, 1 s when writing to a log file |

| Power | 110÷220 V / 50 Hz |

| Dimensions of the case | 660 x 390 x 370 mm |

| The diameter of the “analysis spot” at a distance of 5 m / 3m from the radiometer to the object | 30 сm / 18 cm |

For more information about the MRTR-76 millimeter-wave radiometer (75–110 GHz) and its advanced features, please contact ELVA-1 representative:

Tel: +372 6 888 905

E-mail: sales@elva-1.com